Fundamental Components in Automated Systems

Enabling Precision Motion Control

Bearings function as critical elements in robotics and automation, converting electrical signals into precise mechanical movements. These components establish the foundation for accuracy, repeatability, and reliability across applications spanning from manufacturing cells to medical robotics. As industrial requirements evolve toward higher velocities, tighter tolerances, and extended operational durations, bearing characteristics including rigidity, friction management, and predictable lifespan have transitioned from desirable attributes to essential specifications. The strategic implementation of bearing technology directly influences system performance, energy consumption, and maintenance frequency in modern automated environments.

Operational Applications

Critical Roles in Automated Machinery

Bearings fulfill indispensable functions throughout automation systems. Articulated robot arms incorporate precision bearings in joint and wrist mechanisms to achieve micron-level positioning consistency. Rotary indexing tables and positioning systems utilize slewing rings that sustain combined radial and axial loading during continuous operation. Linear guidance systems employ precision rollerways and ball screws for accurate Cartesian movement in material handling applications. High-speed machining spindles demand bearings with exceptional thermal stability and minimal runout. Each application scenario presents distinct requirements regarding motion patterns, loading conditions, and operational cycles that dictate bearing selection criteria.

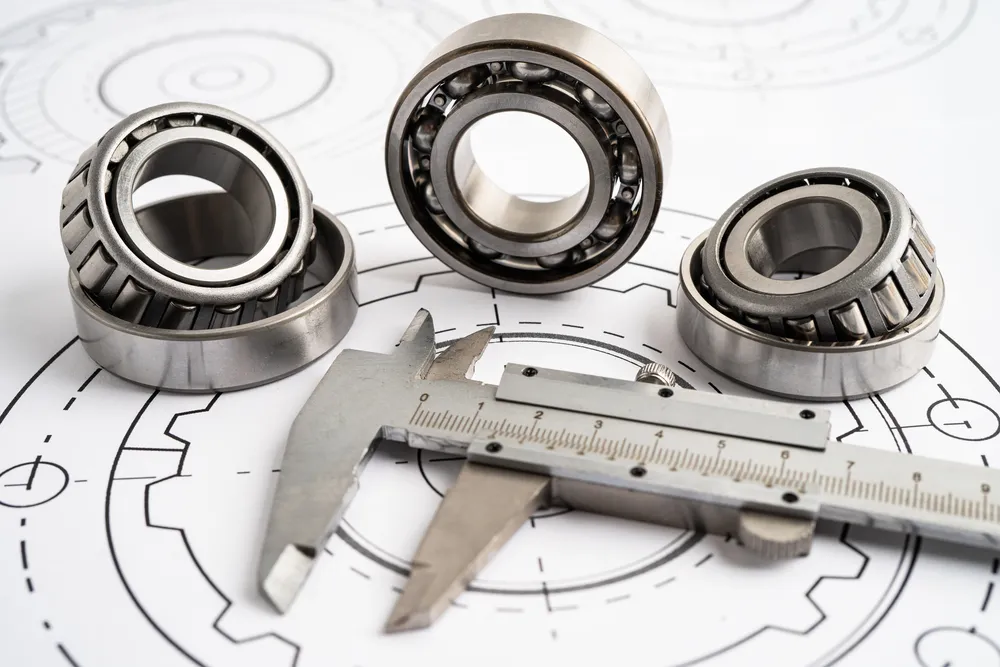

Technical Classification

Selecting Optimal Bearing Solutions

Various bearing families provide specialized advantages for specific automation challenges. Deep-groove ball bearings deliver compact, versatile solutions for moderate loading conditions. Angular contact bearings offer enhanced axial capacity and rigidity through preloaded configurations. Crossed-roller designs provide exceptional moment stiffness within constrained spaces. Cylindrical roller bearings support substantial radial loads in transmission systems. Hybrid ceramic bearings, featuring ceramic rolling elements and steel races, present advantages including reduced inertia, minimized thermal expansion, and extended fatigue resistance for high-velocity or specialized environmental applications.

Precision Performance

Maintaining Accuracy Under Dynamic Conditions

In servo-controlled automation equipment, bearing stiffness directly determines positional accuracy and system responsiveness. Excessive elastic deformation under operational loads introduces hysteresis and diminishes control bandwidth, compromising positioning precision. Engineering solutions include bearing configurations with optimized contact angles, controlled preload methodologies, and specialized geometries that minimize deflection. Crossed-roller assemblies and preloaded angular contact pairs deliver the exceptional rigidity necessary for applications requiring arc-minute level repeatability. Bearing precision classifications must correspond with system resolution capabilities and encoder feedback accuracy to ensure optimal performance.

Contamination Protection

Shielding Strategies for Industrial Environments

Automation systems frequently operate in demanding conditions where particulate contamination, fluid exposure, or cleaning agents threaten bearing integrity. Effective sealing methodologies prevent abrasive particles from penetrating critical interfaces while maintaining lubricant effectiveness. Non-contact shields minimize friction for high-velocity applications, while contact seals utilizing advanced elastomers provide superior exclusion capabilities. Applications with significant contamination risks employ multi-lip seals, labyrinth arrangements, or integrated purge systems. Electrically sensitive environments require specialized conductive seals or grounding mechanisms to prevent damage from stray currents.

Lubrication Methodology

Optimizing Performance and Service Life

Lubrication strategy profoundly influences bearing performance metrics including friction, thermal characteristics, and operational longevity. High-frequency automation joints benefit from low-viscosity synthetic greases with excellent shear stability to minimize heat generation and torque variation. Heavy-load, low-velocity applications require lubricants with enhanced film strength and load-carrying capacity. Regulatory-compliant applications demand certified lubricants meeting industry standards. Permanent lubrication systems must maintain film integrity throughout the designated service interval, while re-lubricatable designs necessitate accessible maintenance points and appropriate purge mechanisms.

Material Science

Advanced Alloys and Surface Engineering

Material selection progresses according to operational environment and performance requirements. Standard bearing steels suffice for controlled industrial settings, while corrosive or humid conditions mandate stainless steel alternatives. Advanced thermal processing enhances fatigue resistance, while surface engineering techniques including nitriding, specialized coatings, and high-hardness platings improve wear resistance and reduce fretting damage. Ceramic rolling elements provide significant advantages through reduced mass, lower thermal expansion, and electrical insulation properties, particularly beneficial in high-velocity, vacuum, or electrically sensitive applications.

Installation Protocols

Proper Mounting Techniques and Tolerance Management

Correct installation procedures ensure optimal bearing performance and extended service life. Implementation requires appropriate interference fits, careful handling to prevent damage during assembly, and specialized tools for installation. Precision applications necessitate calibrated torque instruments, runout verification after installation, and preload validation through axial displacement or torque monitoring. Thermal mounting methods utilizing controlled heating or cooling facilitate the assembly of components with tight interference fits while preserving dimensional accuracy and material properties.

Thermal and Electrical Management

Addressing Operational Challenges

High-cycle automation systems generate substantial heat that affects bearing clearance and lubrication performance. Effective thermal management through material selection, clearance optimization, and sometimes active cooling maintains stable operating conditions. Electrically induced damage from variable frequency drives requires mitigation strategies including insulated bearings, ceramic rolling elements, or grounding devices. Hybrid ceramic bearings demand careful consideration of thermal conductivity and electrical characteristics to ensure proper system performance and longevity.

Validation Procedures

Testing and Verification Protocols

Comprehensive testing validates bearing performance under simulated operational conditions. Analytical methods including finite element analysis and fatigue modeling provide preliminary assessment, while practical testing under representative loads, velocities, and environmental conditions confirms expected performance. Evaluation parameters include running torque, vibration signatures, thermal characteristics, and acoustic emissions. Critical applications requiring exceptional precision demand specialized testing for micro-vibration and noise generation to ensure compatibility with sensitive processes.

Performance Surveillance

Predictive Maintenance Approaches

Advanced automation systems incorporate condition monitoring to detect early indications of bearing degradation. Vibration analysis, acoustic emission monitoring, and temperature trending identify developing issues before catastrophic failure occurs. Lubricant analysis and electrical monitoring provide additional diagnostic information. Condition-based maintenance schedules synchronized with production cycles minimize unplanned downtime, while modular bearing designs facilitate rapid replacement in critical applications.

Selection Framework

Engineering Decision Methodology

Systematic bearing selection requires comprehensive analysis of application requirements. Engineers must define load characteristics including magnitude, direction, and duration across operational cycles. Velocity parameters, duty cycles, environmental conditions, and precision requirements further refine selection criteria. The process encompasses bearing geometry, precision classification, lubrication method, sealing strategy, and material specification, balanced against economic considerations including cost, availability, and lifecycle requirements.

System Integration

Mechatronic Synchronization

Optimal automation performance emerges from coordinated design between mechanical and control systems. Bearing characteristics including stiffness and friction influence control loop tuning, encoder selection, and achievable bandwidth. High-stiffness bearings improve response characteristics and disturbance rejection, while low-friction designs enhance energy efficiency and reduce torque variation. Early consideration of mechanical parameters during control system design ensures harmonious integration between electrical and mechanical components.

Strategic Significance

Enabling Advanced Automation Capabilities

In contemporary automation environments, bearings represent critical elements that determine system productivity, reliability, and precision. Appropriate bearing selection, implementation, and maintenance transform theoretical motion requirements into practical, reliable performance. Engineers who recognize bearings as integral system components rather than standardized parts achieve superior automation solutions characterized by enhanced accuracy, extended service life, and reduced operational costs. The continued evolution of bearing technology remains essential for supporting advancing automation capabilities across industrial sectors.